Mother India Forming unveiled its Humanoid and

Quadruped Robots at EXCON Bengaluru, advancing precision cold-roll forming. The

humanoid ensures high-accuracy production, while quadrupeds provide continuous

factory surveillance. These AI-driven systems enhance efficiency, and support

the “Made in India” vision, reinforcing the company’s leadership in smart,

sustainable manufacturing

Bangalore, December 10 :

Mother India Forming, a leading Indian manufacturer in the business of

precision cold-roll formed components, showcased its pioneering Humanoid and

Quadruped Robots at EXCON Bengaluru to further enhance operational efficiencies.

This marks one of the most advanced robotic deployments in India’s precision

sheet-metal cold-roll forming industry.

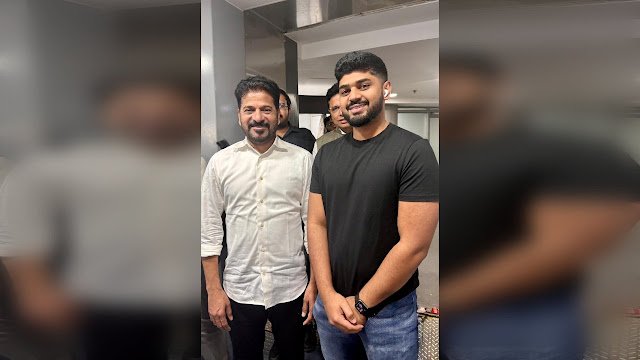

Speaking at the occasion, Dhirendra Sankhla, Director

– Mother India Forming explained that – “Mother India Forming is stepping into

a new era of smart manufacturing with the introduction of a state-of-the-art

humanoid robot on the shop floor, alongside quadruped robotic systems for

autonomous surveillance. This marks an important milestone in our journey

toward a highly automated, AI-driven ecosystem. The newly deployed humanoid

robot has been engineered to execute operations that require extreme

consistency and micron-level precision. Beginning with automated

pick-and-place, process safety checks, factory vigilance & enabling continuous

monitoring of restricted zones and standardized material handling, the humanoid

enhances every stage where repeatability defines product performance.”

“As global OEMs tighten quality checks, safety, and

delivery benchmarks, India is rapidly strengthening its engineering

capabilities. Our latest robotic integration signifies a decisive step toward

creating smart, autonomous, and globally competitive manufacturing ecosystems —

fully aligned with the national vision of Made in India,” Dhirendra Sankhla

added.

The induction of the humanoid robot is expected to

significantly cut inspection cycles, reduce manual dependencies, bring

autonomous dimensional & profile verification, online defect identification

through image intelligence, real-time accuracy logging, analytics, and

data-driven corrections, ultimately leading to zero-defect manufacturing – the

company said.

“Our goal is to integrate robotics not just as an

automation tool, but as a partner in precision, helping us deliver the

best-in-class components to the industry. The future belongs to robotics,

automation, and data intelligence and this will shape the manufacturing sector

of tomorrow. Mother India Forming is proud to contribute to India’s journey

toward global leadership in precision cold-roll forming,” says Dhirendra

Sankhla.

Mother India Forming has developed a fully integrated,

360-degree manufacturing ecosystem where sheet metal cold-roll forming,

fabrication, finishing, and powder coating all operate under one roof. This

consolidation drastically reduces multi-vendor logistics and associated Scope-3

emissions for primary equipment manufacturers. The company is also expanding

its renewable energy capacity from 150 kilowatt to 1.25 megawatt of solar

power, complementing its already low-carbon operational model.

Global industry outlooks project a 7–9% compound

annual growth rate in demand for precision-formed components through 2030.

Growth is being driven by sectors such as automotive and electric vehicles,

renewable energy, infrastructure, engineered structures, warehousing systems,

construction, and electrical equipment—industries increasingly requiring

lightweight, high-strength, dimensionally stable components with low

environmental impact.